Bag Filter Design Handbook Pdf

Bag filter design handbook pdf. Pleated bag 223 Pleated bag The filter media is usually a felted material composed of cellulose polypropylene or other flex-resistant material. And retained inside the filter bag is one of the significant characteristics of the bag filter system. Download Full PDF Package.

Differential pressure monitoring is always in place to give advance warning to the operator that the. For bag filters literature references mention. Since there are no openings in the fabric material there is no ini-tial cake buildup period.

Essentially all pleated filters are shorter than pulse jet bags. Air Pollution Control and Design Handbook Part I. If you are author or own the copyright of this book please report to us by using this DMCA report form.

Its free to sign up and bid on jobs. What can I do for you. Inlet Unfiltered Filter bag sealing Filter bag supported by a restrainer basket Outlet Filtrate Bag filter housings may contain between 1 and 24 filter bags depending on type and design.

Our engineering team has 30 years of experience in surveying the output and needs of various plants and will study yours to find an appropriate solution to reach your desired emissions reductions. 1 Handbook of Fabric Filter Technology. 33 Full PDFs related to this paper.

Dust Collection Technical Handbook Index Page 2 Glossary 35 Filter MediaFibers 42 GasAir Tables Electrical References Missing Section 54 Industrial Ventilation References 59 Material Properties 82 Miscellaneous References 87. Bag Filter Calculation1234567 IP. A collecting line merges the different streams through the filters into one transfer line.

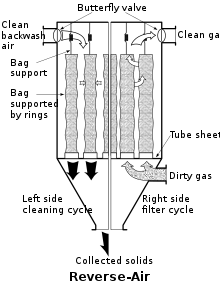

INSERTABLE BAG FILTER PDF DOWNLOAD INSERTABLE BAG FILTER PDF READ ONLINE bag filter design handbook pdf bag filter specification bag filter in cement plant bag filter diagram bag filters in cement industry pdf bag filter efficiencybag filter design calculation pdf bag filter working principle. Area of single bag Ab 314 01 50 157 m2 N u m b er o f b ag s N 150 9 5 5 4 9 6 1 5 7 The numbers of bags required for a continuous removal of particulate matter are 96.

AFR Handbook Vol 1 Contents.

To determine the appropriate filter size we must study the air-. Fabric Filter Design Variables 20-395 3-5 Figure 3-2. 02 28112008 ISO 90012000 4 DESCRIPTION OF COMPONENTS 41 Filtering Bags These are filtering elements made in needled felt through which the air and dust separation takes place as the air. Fabric Filter Systems Study. A Handbook for Accessories Designers. Take the CFM of the system and divide it by the total filter cloth area to get your air to cloth ratio. These fabric filters generally made from woven and needle felt of natural or artificial fibers. The unique feature of a pleated filter is the design of the filter element. Conditioning There is much more into the design of.

Since there are no openings in the fabric material there is no ini-tial cake buildup period. Mesh filter bags are supplied with a plain finish as woven. Some pleated filters have simple. These fabric filters generally made from woven and needle felt of natural or artificial fibers. Collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector. Download Full PDF Package. HVAC Design for Cleanroom Facilities Course No.

Post a Comment for "Bag Filter Design Handbook Pdf"