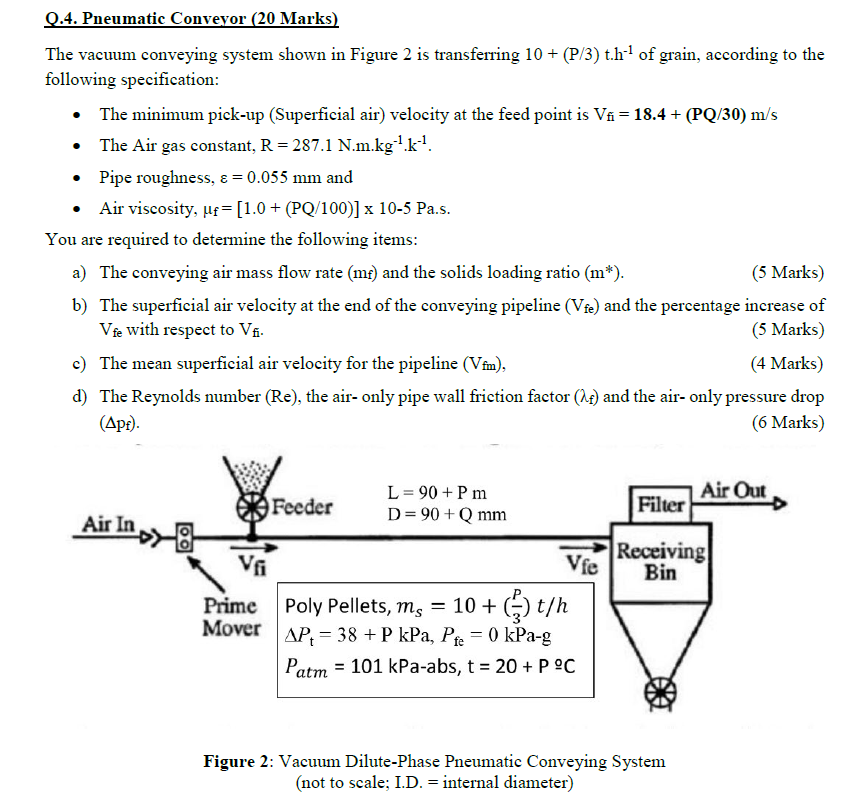

Vacuum Conveying System Design Calculation

Vacuum conveying system design calculation. In vacuum- and pressure pneumatic conveying calculations the used product properties are identical. Smooth level dry. Air-powered conveying systems from Air Con Tech Systems are ideal for the beverage and can industry.

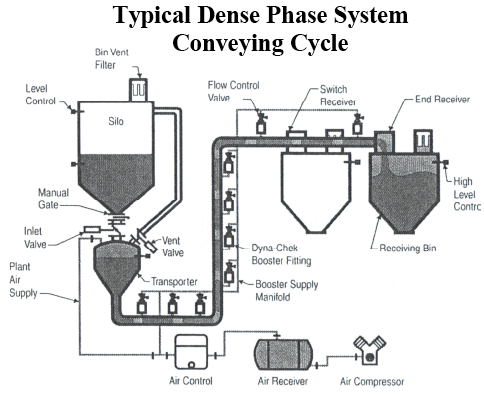

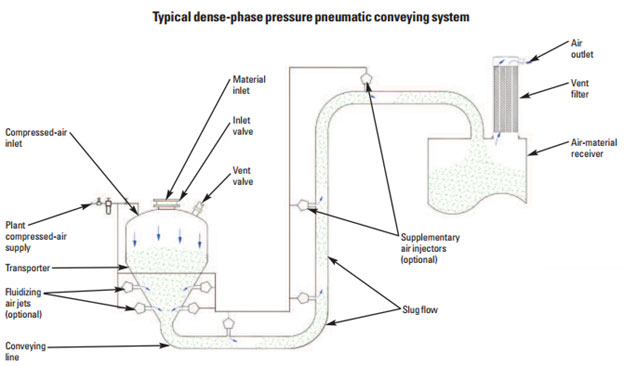

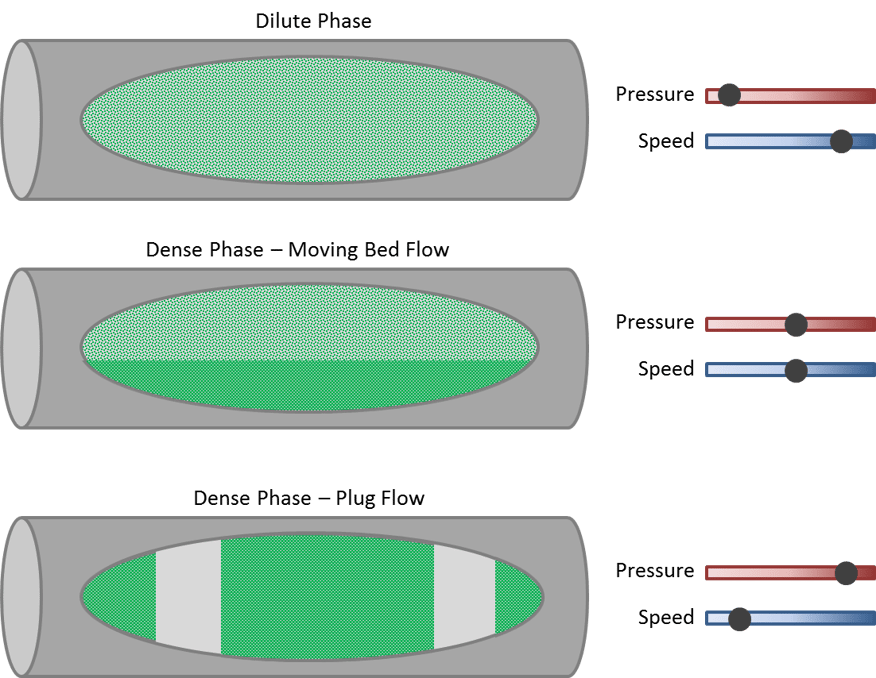

Vacuum flow lbh It is generally the case that in dense phase because the material moves in the form of 2. No moving parts to jam. Steel sheets stacked on a pallet.

Includes material saltation velocity calculator tools. They help businesses save time limit labor and other expenses and. Vacuum Conveying is the process of moving bulk dry materials such as powders from place to place within a plant.

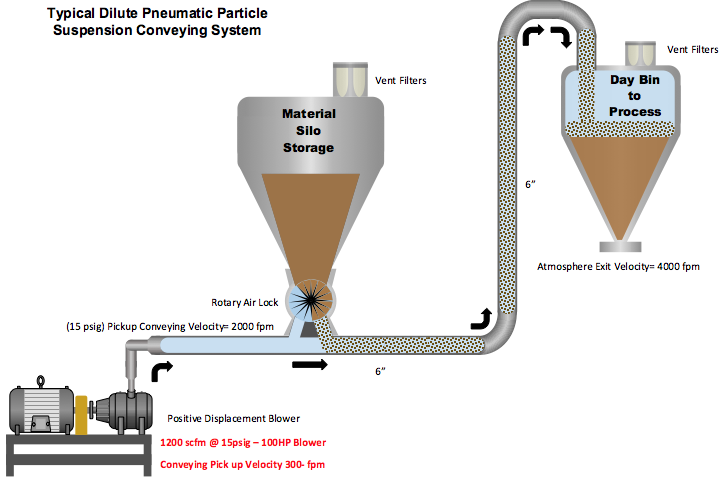

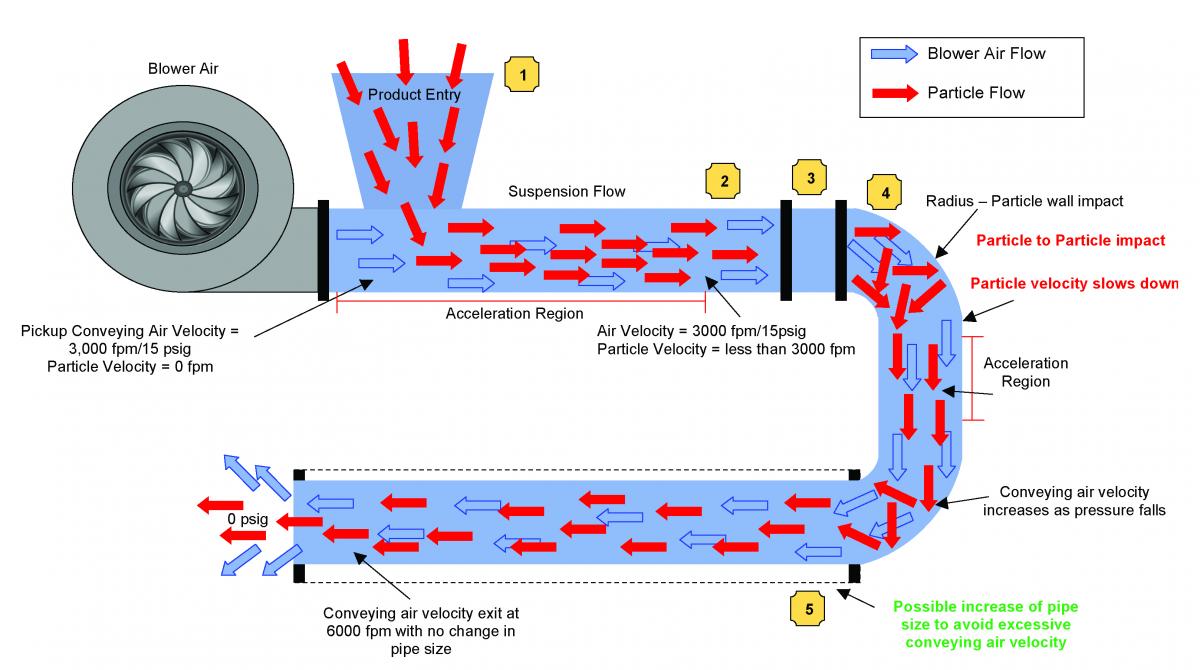

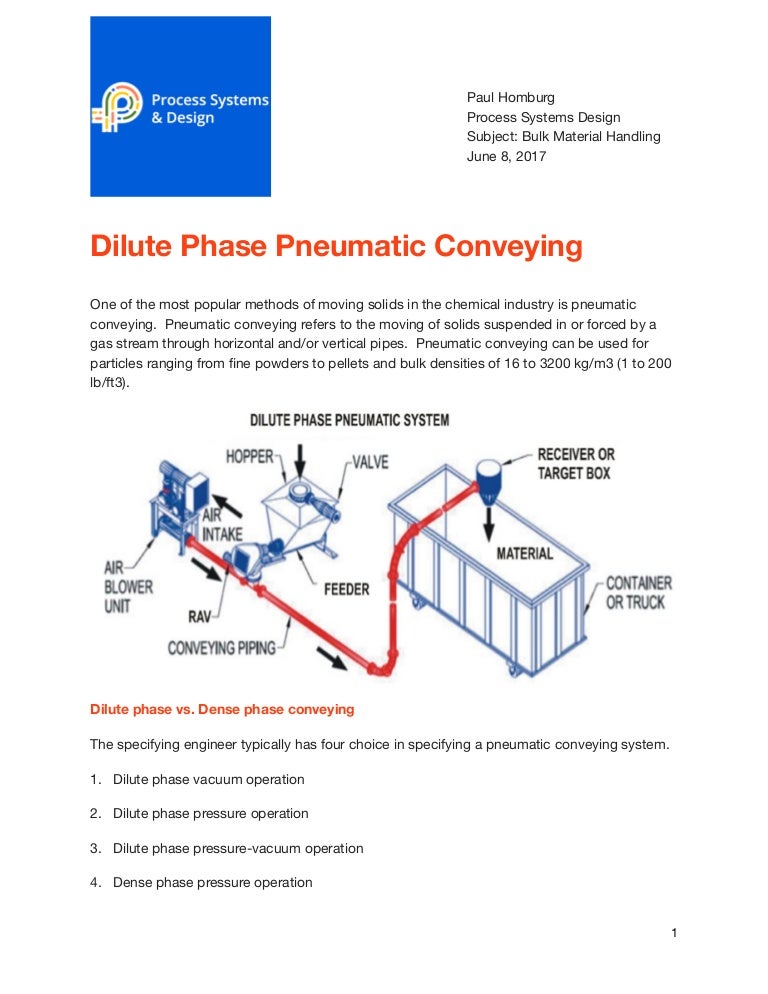

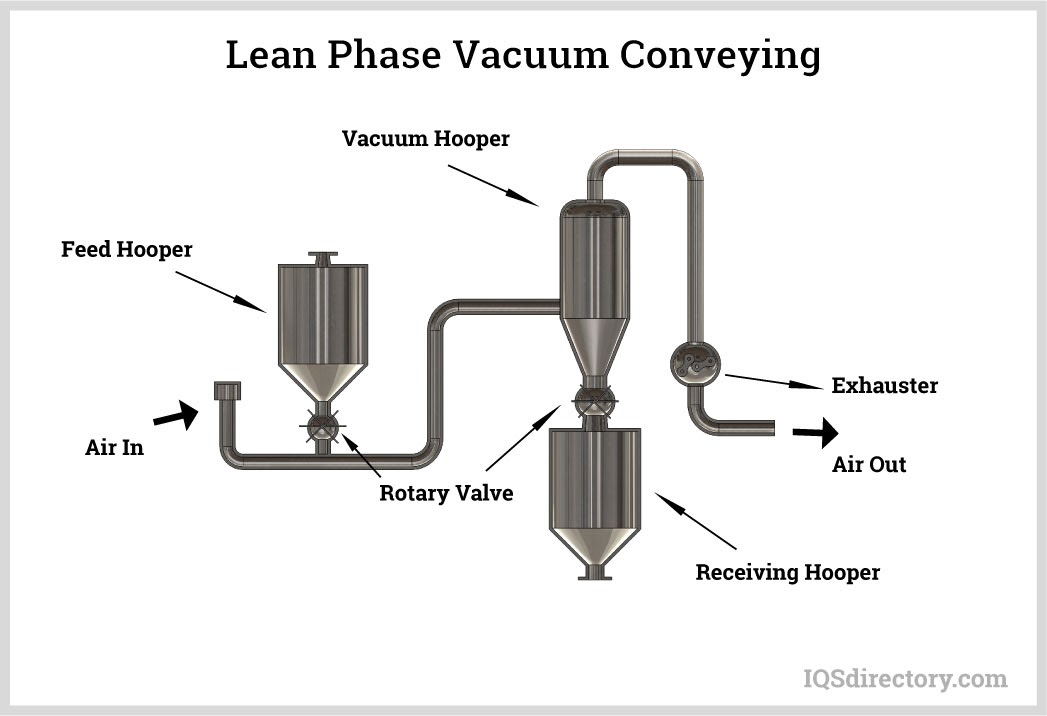

Vacuum Conveying is the process of moving bulk dry materials such as powders from place to place within a factory using suction. It is now a well-established practice and is primarily concerned with the prediction and. A conveying system of any kind is used to transport a material from one particular place to another.

For the chosen method of pneumatic conveying air is used as the. In the area of food processing the pharmaceutical and chemical industry and for material feed in plastics processing suction conveying is indispensable when powder or granular materials. Ad Find a distributor in your area or contact us for more information about our products.

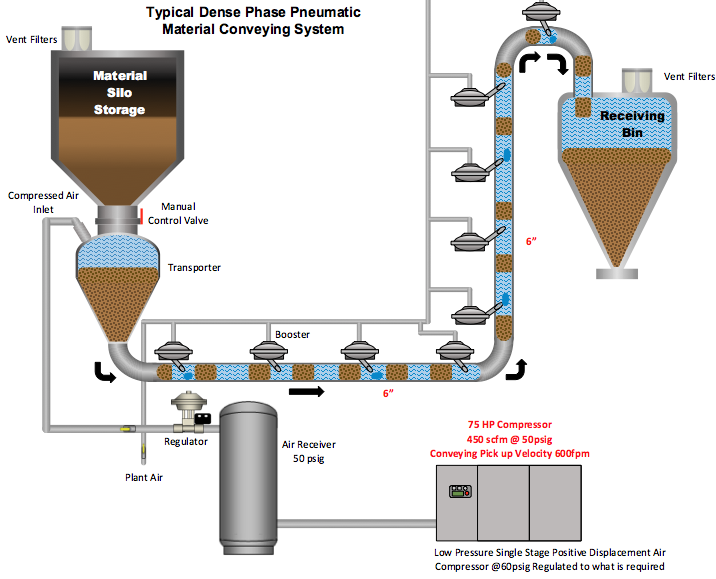

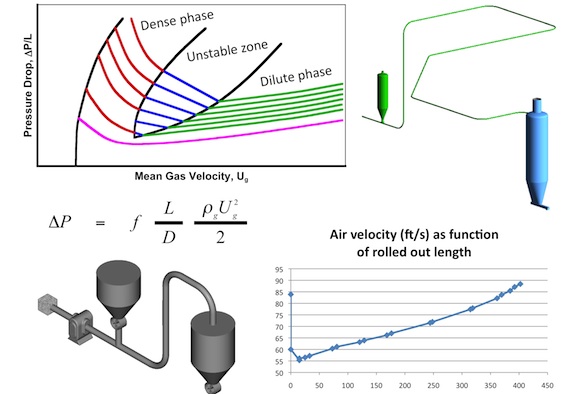

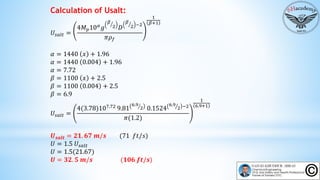

How does Vacuum Conveying Work. Calculate and display dilute dense and mixed modes of conveying. Determine the Saturation S hpton HP pipe velocity v and Pressure Factor PF values for the conveyed product from the published saturation table.

Fluid Flow systems is a well-established name in the sector of manufacturing Designing and Exporting of Vacuum employed conveying systems. Uses compressed air to move wet or dry chips to a drum.

Conductance limiting components surface outgassing.

Vacuum Calculations Page 5 System Design. Calculate and display dilute dense and mixed modes of conveying. No moving parts to jam. Vacuum flow lbh It is generally the case that in dense phase because the material moves in the form of 2. Design and troubleshoot both pressure and vacuum systems. Vacuum conveying systems are particularly suitable for systems which convey materials at low to moderate capacities over medium distances from multiple points to a single destination. Vacuum Conveying is the process of moving bulk dry materials such as powders from place to place within a factory using suction. Determine the Saturation S hpton HP pipe velocity v and Pressure Factor PF values for the conveyed product from the published saturation table. In vacuum- and pressure pneumatic conveying calculations the used product properties are identical.

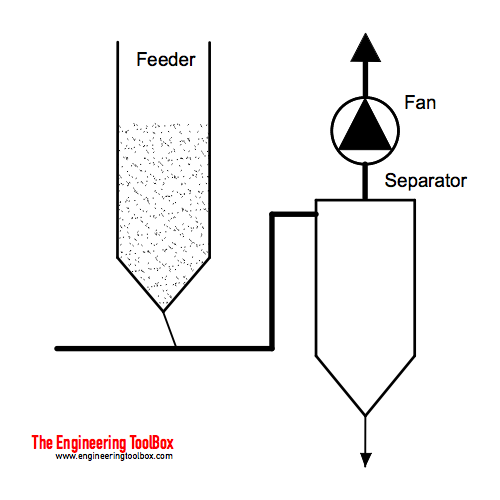

For the chosen method of pneumatic conveying air is used as the. Ad Find a distributor in your area or contact us for more information about our products. A typical vacuum conveying system Vacuum is generated by a compressed air. Motivation This effort is undertaken to provide an understanding of the critical issues eg. Vacuum flow lbh It is generally the case that in dense phase because the material moves in the form of 2. Uses compressed air to move wet or dry chips to a drum. A conveying system of any kind is used to transport a material from one particular place to another.

Post a Comment for "Vacuum Conveying System Design Calculation"